Profiled sheet is a material for various constructions and facing events, which is now literally at the peak of popularity.

How is a profiled sheet

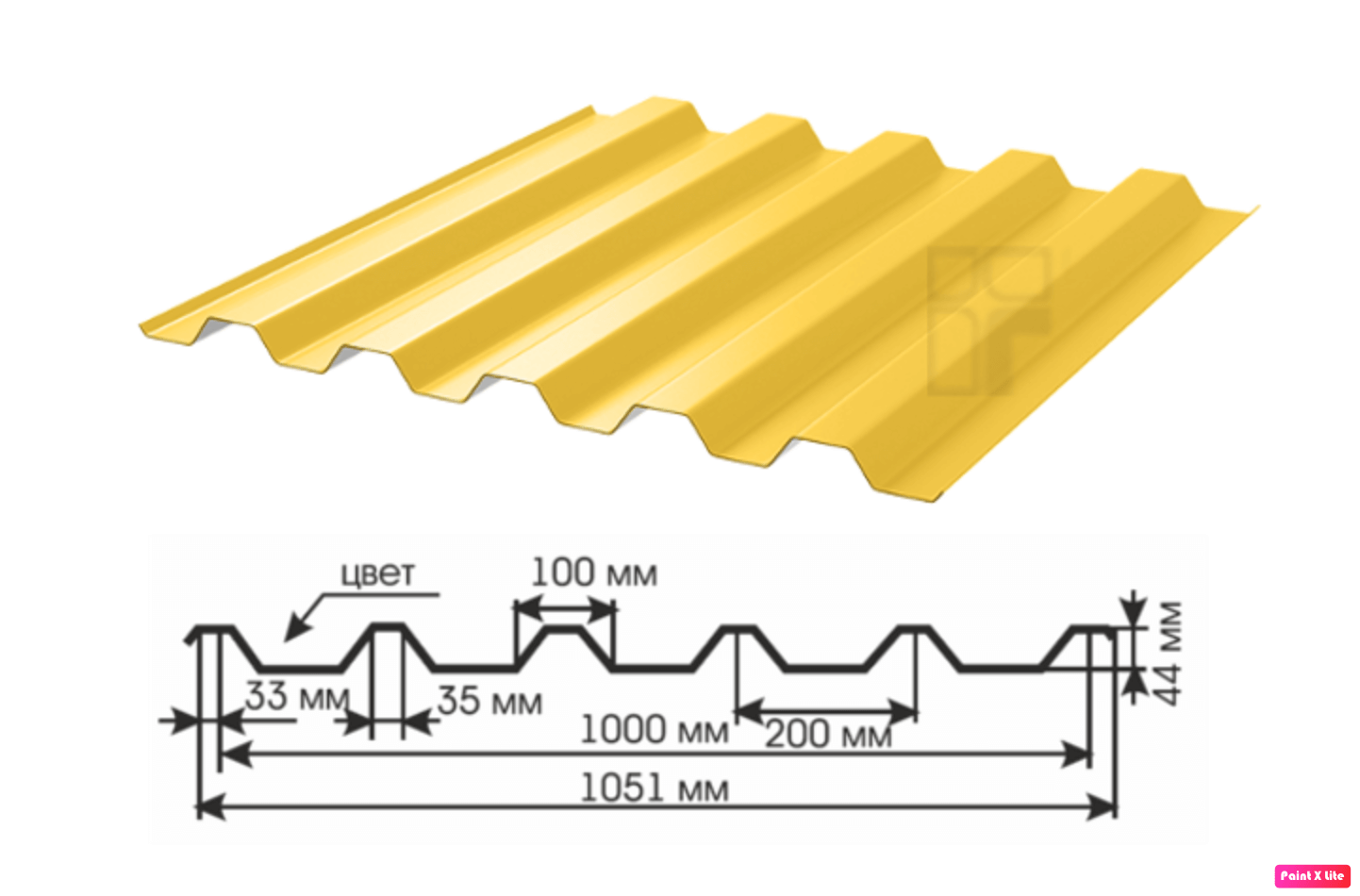

The starting material from which the profiled sheet is made is stainless or galvanized steel. Due to rolling machines, the steel sheet is processed in such a way that a corrugation appears on it, that is, a wavy section. A protective and decorative composition is applied to both sides of the sheet. Previously, ordinary paint for metal was used. Now there are mostly samples coated with polymeric compositions. It would seem that the material is simply arranged. And yet he has enough advantages.

What are the advantages of profiled sheet

1. Bending strength. Due to the presence of corrugations, the profiled sheet does not deform even under intense loads. It perfectly resists even strong winds, which is why it is often used to create fences.

2. Mechanical strength in general. We are talking about a material made of metal, therefore, regardless of the surrounding conditions, the profiled sheet does not crack or split like slate. Even if deformations appear on it, it can be restored.

3. Wide circulation area.It will be possible to use such a simple product when erecting fences, arranging a roof, facing various outbuildings on the site.

4. Ease of handling. To fix the material on a rough basis, you do not need to have special knowledge. The material will be able to mount and on its own correctly.

5. Cheap. Finally, professional sheet is inexpensive, so it is great for cost-effective repairs.

What are the problems of profiled sheet

Among the minuses, perhaps, only the modest appearance of the material should be mentioned. Despite the presence of a decorative layer, the profiled sheet still looks inconspicuous. If the owner wants to get a particularly presentable roof or spectacular cladding, he needs to turn to other options.

It should also be remembered that stainless steel, although it is called that, can still become corroded. First of all - in those areas where it had to be cut during installation. Cut lines are best treated with anti-corrosion compounds. Taking this into account, the owner will be able to competently use the profiled sheet in his repair or construction.