Meaning of indicators and codes

Soon after buying a washing machine, the problem arises of how to properly operate the appliance. Any device has its own subtleties in the name of washing modes and functions. The regulators and buttons of the device can be signed in English or Russian, or you can see signs combined with inscriptions, or simply some pictures.

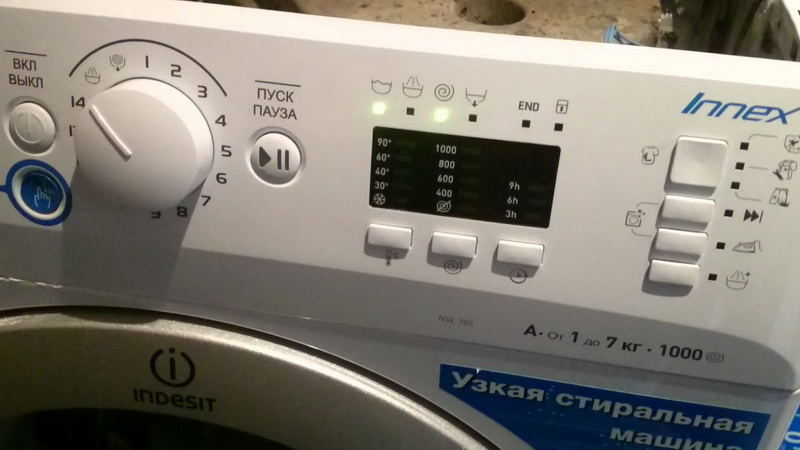

A working Indesit washing machine systematically executes the task plan by the user, notifying about the ongoing stage with indicators, changing the ordinary sound to minor stops. The breakdown immediately announces itself, with an abnormal beep, creaking, flickering or a complete stop. On devices with a monitor, combinations of errors are displayed on the scoreboard, in machines where there is no monitor, errors are presented in the form of a combination of flashing lights.

Troubleshooting and Recommended Repairs

To detect a defect in the washing machine, it is necessary to carry out diagnostics. Self-diagnosis is a built-in function of any modern machine. Naturally, the device will not show which spare part needs to be changed, but will indicate the direction in which to look for damage. All information about the damage to the mechanism is displayed on the scoreboard, in the form of specialized combinations, for example: F01, F02, F03, F04, F07, F13 and others.

The explanation of the errors of washing machines without a display is done by the number of blinking LEDs, the values of all indicators are summed up, and the resulting number will be the error number.Usually, failure codes and their decoding are written in the operating instructions. Some damage can be repaired by yourself, but most of the breakdowns require the intervention of a master.

First of all, you need to remember that a failure incident is not always a fatal result. Sometimes the codes of washing devices show a slight braking of the electronics. It is advisable to disconnect the machine from electricity for half an hour, and then turn it on. This process should undoubtedly be the first in the mechanism repair procedure. If a satisfactory result is not achieved, you must read the instructions.

No1 motor malfunction (F01, F02)

An error on the display of the Indesit F01 washing machine is extremely rare. This combination informs about a malfunction that is associated with the engine of the washing machine.

They arise for the following reasons:

- the electrical outlet and the network cable of household appliances are faulty;

- corrosion of the contacts on the motor block has formed;

- motor winding burned out;

- the carbon brushes of the commutator motor are worn out;

- The control panel amplifier is defective.

Error F02 means that the circuit in the tachometer is broken, as a result, the electric motor does not function.

The appearance of a failure can be triggered by various reasons, we list them:

- jamming of the motor rotor;

- defect of the tachometer responsible for the revolutions of the drum;

- failure of the electronic control unit;

- faulty contacts on the board.

No2 sensor failure (F03, F04, F07, F13)

Information code F03 appears on the display when the washing machine cannot heat the water to the required temperature. The reason for the failure may be sticking of the heating element or a sensor malfunction. In case of inaccurate operation of the sensor controlling the water level, the combination F04 will appear on the display.The source of the breakdown can be both in the sensor itself, and in interruptions in communication between the sensor and the electronic control unit.

The washing device can display error F07 on the electrical panel, which indicates the tactless operation of the electric heater. Code F13 notifies of malfunctions in the temperature control circuit for drying clothes.

No3 drain and fill problems (F05, F10, F11, H2O)

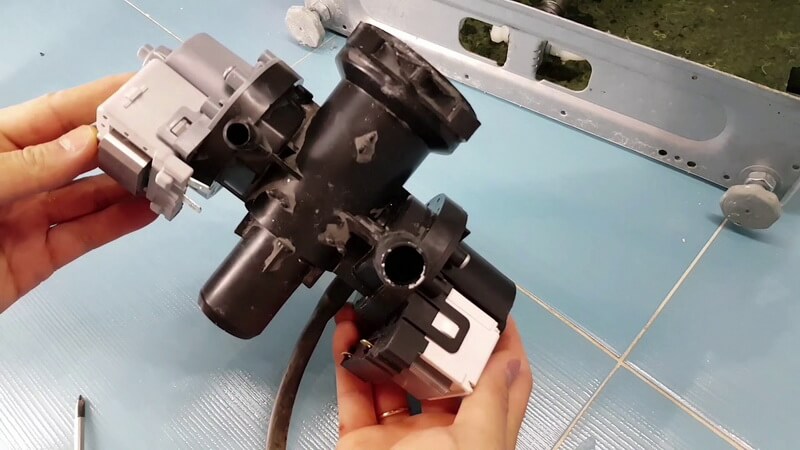

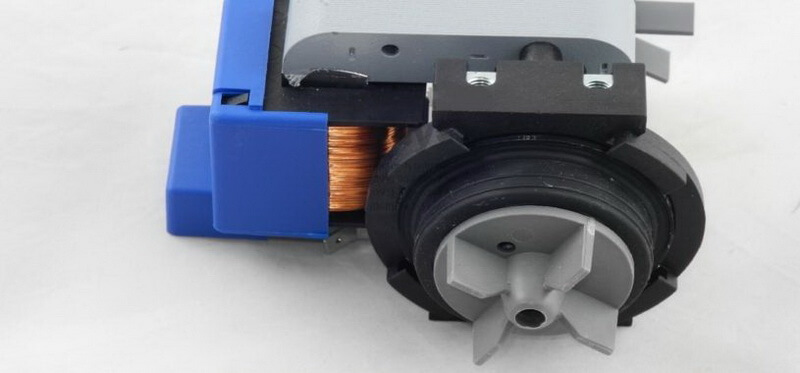

This group of errors is associated with the actions of the drain system. There are only two problems that can trigger the F05 code, these are: a drain pump problem and a breakdown of the water level sensor in the tank. Also, the absence of a signal from the water sensor of the equipment can give error code F10, as a rule, it indicates a defect in the pressure switch. If the device issued code F11, then there were serious problems with the system for draining water from the tank.

The reasons for the breakdown may be a failure in the service of the pump, control module or pressure switch. Most often, problems are caused by the presence of debris in the filter. Typically, washing machine error codes start with the letter F and end with a number, but the H2O error stands out among them. The number zero in this case was replaced by the letter o, and the chemical formula of water was obtained. This is done on purpose to make it easier to remember the error and its decoding. This combination indicates problems in the water inlet system.

No4 electronics failure (F06, F09, F12, F18)

The situation when error codes for washing machines F06, F09, F12 or F18 are displayed on the screen means that the central board has broken. If the code F06 occurs, it means that there are problems in the control, and the machine does not respond to instructions.

Error F09 indicates a malfunction of the control module, the system does not respond to button presses. This is rare, but very dangerous.Fault code F12 is displayed with symptoms when the contact between the control and power systems has disappeared. The technique may issue an F18 error in a situation where there are problems with the electronic unit. The processor is responsible for selecting washing programs, controls the drain and water intake valves, and displays the operating mode of the device on the panel.

No5 faulty heating element (F08, F14, F15)

The tubular electric heater of the heating element makes it possible to heat water and dry clothes in an automatic washing machine. Error F08 occurs after the water is drained, but the heating element continues to heat up. The cause is a faulty electric heater control relay.

Error code F14 is displayed when the drying heating element malfunctions, a sign of a malfunction is that the laundry is still damp after drying. Error F15 inherent in washing machines with a drying function. It indicates the absence of contact between the drying relay and the heating element. The failure manifests itself as follows: the washing process has passed, but drying does not occur. The problem can be both in the power circuit and in the sticking of the contacts of the washing machine.

No6 incorrect drum position (F16)

Error F16 is typical only for washing machines with a vertical load of laundry. If the signal appears, then the drum has stopped spinning or the wash has not started. This failure is also often referred to as the "drum parking error".The vertical loading mechanism must be fixed with a special button before turning on the machine, otherwise the hatch will open during circulation and may break the equipment.

To prevent this from happening, you need to disconnect the machine from the network, and try to turn the drum inside with your hand, if the drum does not scroll, a foreign object may have got in. If the drum scrolls, you need to leave the machine turned off for half an hour from a quarter, so it will reboot.Look around the drum hatch, make sure the hatch is in place, if it is not, it probably leaned back during the wash and blocked the drum. We check the control module for serviceability, in case of a malfunction, we replace or repair the module. You also need to test the hatch blocking mechanism.

No7 hatch sealing does not work (F17)

The cause of the error code sma Indesit F17 may be a loosely closed manhole cover. At the same time, the "Lock" indicator lights up, and washing does not happen. It is advisable to simply close the lid tightly. If this cannot be done, consider for foreign objects or damage between the entry opening and the hatch valve. The door may not close if the drum is overloaded. Another version to solve this problem is to replace the sunroof blocking device. Another option is a low voltage network. If the electricity does not reach 220 volts, household appliances of the same size will not turn on. In the event that there was a situation that did not fit any description of errors, you will have to go to a service center.

No8: violations in the functionality of bearings

Unusual behavior of the washing machine during operation indicates a malfunction.If the appliance began to rumble, creak, make noise or move along the floor during washing and spinning, most likely the problem lies in bearing failures. The first and main factor in bearing wear is damage to the sealing collar. Its task is to ensure the tightness of the tank, preventing water from spilling out of it.

Water helps wash out the lubricant, in such a situation the balls turn to dry, and this leads to damage to the part. Bearings can also collapse due to depreciation. In this situation, oily traces of lubricant can be seen on the inner area of \u200b\u200bthe housing. It is not permissible to continue to use a mechanism in which the bearings are broken, this can lead to catastrophic damage, this is the destruction of the nozzle or half shaft.Modifying the seal and bearings is hard work, rotating them is considered a major overhaul and best left to a craftsman.

No9: Detergent remains in the tray

The situation when the powder remains in the container in the washing machine is extremely popular, and often not associated with severe breakdowns. First of all, you need to check whether you put the washing powder in the correct compartment.

You may also have added a lot of laundry detergent, and therefore not all of it was washed out of the reservoir. Often the powder is left unused due to pipe pressure problems. It is necessary to check whether the water is supplied with sufficient pressure. To do this, open the mixer tap and observe the jet. Poor water pressure and there is a malfunction.

Clogging of the pipeline flushing the powder into the tank is a common problem with the device. Water enters the dispenser, but due to a forgotten pipeline, it cannot flush all the powder into the tank.Another culprit for damage is poor quality powders, they accumulate in lumps and stick to the wall of the tray. In addition to the filter, the hoses that connect the water supply valve to the powder tray may become clogged. The powder receiver should be cleaned regularly. If after washing, after some time, the problem occurs, it is necessary to look for other sources of the problem. It is likely that the powder does not leave the tank immediately, for several of the reasons mentioned above. And only after neutralizing the problem, the washing machine will be able to function effectively. If you yourself could not fix the breakdown, contact the master.

conclusions

Devices brand Indesit refers to reliable technology. Due to the standard design of the device and the presence of a self-diagnostic system, this helps to quickly eliminate significant breakdowns. As you may have noticed, washing machine error codes are not a panacea for solving all problems.The microcontroller displays only the consequence of the malfunction, and not the source of their failure, of which there may be several. They only indicate possible problems. This saves time for repairing equipment, as they immediately eliminate the excess in the list of possible breakdowns.

Useful video on the topic

On the video, you can get acquainted with the ways to troubleshoot washing machines, indicated by different information codes. From a useful video, you will learn how to act when a machine breakdown is detected on your own, and when to use the services of a master.