Probably, all of us have a washing machine at home, but almost none of us knows about its device. However, the device of a washing machine may be of interest to everyone who decides to repair this type of equipment. Or you want to repair your washing machine yourself and for this it is also advisable for you to study the device.

That is why here we will analyze this question and try to fully answer it.

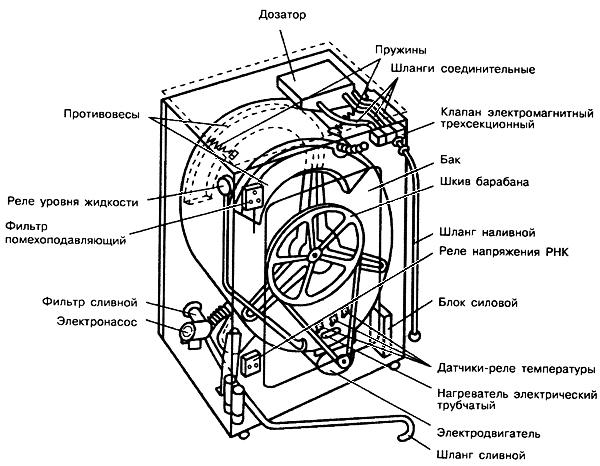

Washing machine diagram

Before proceeding to a phased analysis of all the details and considering how the washing machine works in detail, let's first look at the drawing of the washing machine device, which will immediately tell a lot and give you a general idea.

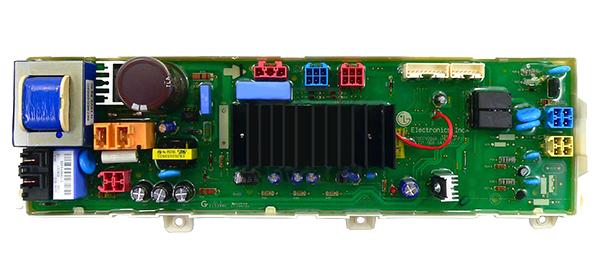

Control module and electronics

We will start, of course, with the most important thing in the washing machine, and, probably, many might think that this is a washing machine tank or a drum. But no, the main detail, without which everything else simply will not work, is the control module. This part is the "brain" washing machine, it monitors the operation of the entire system and gives timely signals to the engine and other elements about the start and end of work.

It is the control module that contains the "list" of all washing programs and executes them accurately.For each washing machine, it can be different, one is “smarter”, the other is not, but the task is the same for everyone. If the module fails, then the washer starts to fail or stops working altogether. Replacing such a block is quite an expensive procedure.

In order for the control module to be able to control the entire washing process, it needs input signals that are provided by various sensors.Let's take them in order.

Water level sensor

We have already considered in detail pressure switch deviceand you can read more about it. Here we will briefly mention it: this sensor is designed to monitor the water level in the washing machine tank. This is necessary so that the control module knows whether there is water in the tank and how much of it. Together with this sensor, there is an air chamber in the washing machine, which supplies pressure to the sensor depending on the fullness of the tank with water.

Thermostat

This sensor is usually installed at the bottom of the tank, partially recessed into it. Its job is to determine the temperature of the water in the tank and send the readings to the control module.

Tacho sensor

This sensor is needed in order to control the engine speed of the washing machine. Without it, it would not be possible to apply different speeds in different washing modes and during the spin cycle.

Other electronics

The rest of the electronics include a front control panel with indicator lights and a display, as well as various relays and wires that connect all components together.

Performing elements

When the control module has received all the necessary data from you through the control panel, as well as from the sensors about their condition, it gives the necessary commands to the executive bodies, which put the entire mechanism into action.

Hatch door lock

Before the start of washing, a signal is sent to the lock of the hatch door, which blocks it until the end of the wash.

Water supply valve

After that, you need to pour water into the washing machine, for which the water supply solenoid valve opens, which closes after a signal comes from the pressure switch that the tank is already full.

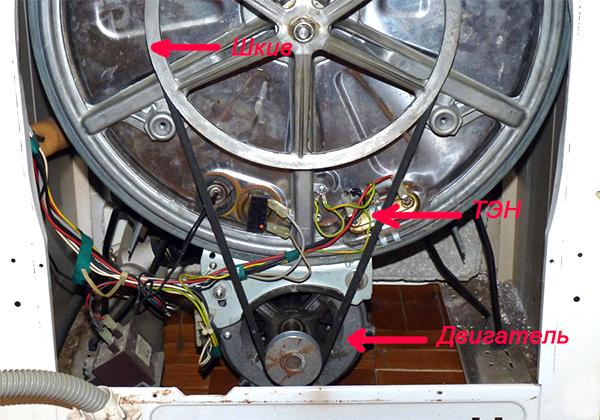

Engine

In order to put the tank into action, the necessary signal is sent to the engine, which begins to rotate.The engine itself, using a belt (in conventional washing machines) or directly (in machines with an LG direct drive device), begins to rotate the drum through a pulley with the required speed. Turns and rotations in the right direction, as well as the number of cycles, are fully regulated by the control module.

heating element

To heat water in the design of the washing machine, a heating element is used - a heating element, which, receiving the necessary signal from the module, starts heating the water and heats it to the desired temperature, after which it turns off. Please note that the heating element becomes covered with scale during prolonged use, as a result of which it may fail. That's why The heating element in the washing machine must be regularly cleaned in a timely manner.

If necessary, the temperature can be maintained by turning the heating element on and off using a thermostat.

water pump

After the laundry has been washed, the control module sends a signal to the pump (drain pump), which starts rotating and pumps out water from the tank, draining it into the sewer.

Also, the pump is connected at one end to the water drain valve, which can be unscrewed for cleaning.

Washing machine tank

The next element in the device of the washing machine is the tank. You can clearly see it on the diagram of the washing machine, it occupies most of the entire unit, since it contains a drum for loading laundry. The tank itself today is made of plastic and is a kind of sealed container inside which the drum is placed, as well as the heating element of the heating element.

The tank consists of two halves, which can be fastened together using metal brackets or bolts on different models. Rubber fittings for filling and draining water are suitable for the tank.

Since the weight of the washing machine tank is large enough, it is mounted on springs to the body of the machine from above, and from below with the help of shock absorbers to mitigate vibrations.

Drum

The drum of the washing machine is a stainless steel mesh container, which is designed to rotate, thereby washing clothes. Different models of washing machines use different EcoBubble and pro technologies in the drum. But the principle of action is the same everywhere. The tank rotates, thereby constantly turning the laundry and washing it.

It happens that the drum in the washing machine does not rotate. The reasons for this malfunction can be very different - deal with them and find out how to repair the rotation of the drum in the washing machine you can also visit our website.

From the front of the tank, the drum is connected to the tank with a rubber cuff so that everything is airtight. At the rear, the drum shaft exits the tank through a hole into which the bearings and the stuffing box are inserted. You can see more details in article on bearing replacement.

Body and other parts

We have analyzed the main essence, but in order to fully know how the automatic washing machine works, it remains to pay attention to some more details.

Powder supply

Powder for washing is placed in a tray, which is located in the dispenser hopper. This bunker is a plastic box, to which pipes for water supply from the solenoid valve are connected.

Counterweights

Since during washing and especially spinning a large imbalance of the washing machine tank occurs, vibration is inevitable, in order to compensate for it, the lower and upper counterweights are attached to the tank. They are concrete bricks that are screwed to the tank.

Frame

If all of the above parts are removed from the washing machine, then there will be one body, a load hatch door and a top cover.By themselves, they do not carry any benefit, but are the frame in which the rest of the design of the washing machine exists.

Hoses

The machine also has hoses for supplying and draining water. The water supply hose is screwed to the inlet valve and can be easily disconnected if necessary.

The water drain hose is attached to the pump and you will need to use a tool to replace it.

Also in the machine itself there are various small tubes that connect the elements to each other.

Comments

is it possible to start a washing machine without water supply

good day ... .. if the machine whistles while rinsing, what could it be ???

Good afternoon! Thanks for the interesting article, very informative.

Such a question - if during washing plastic elements flew off the clothes and after washing they were not in the drum.Where could they go and how critical is it for the further operation of the machine?

Thank you!

The hotpoint at work was flooded to the filter (it was also flooded), it was not turned off from the outlet. But the machine was not turned on. They put 25 thousand on the account. They say they're brainwashed. Could this be? After all, the module is under the cover. I feel like I'm being deceived.

I have a Veko machine. At start-up, no water enters the powder compartment, and during the final rinse, no water enters the conditioner compartment. Only enters the simple rinse compartment. Please tell me what could be the reason. Thank you!