When equipment breaks down, the easiest way is to send it to a landfill or sell it for spare parts for a penny. If you show a little imagination and make an effort, even a failed washing machine engine will come in handy on the farm. Using photos and videos of creative masters, you can make crafts from a washing machine with your own hands, for example, a fully functional animal feed cutter or a brazier for a summer residence.

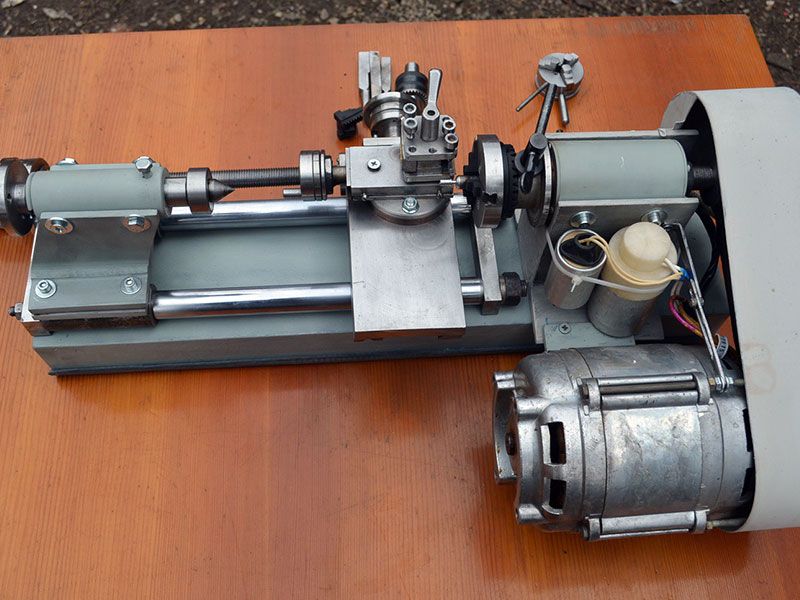

Wood lathe

What can be done from an old washing machine? For example, a lathe, for its base of a homemade lathe, it is good to use an asynchronous motor, with two adjustable speeds. The main thing in the device is to make a stable base. The frame is usually made of profiles and metal corners.

The support structure and the motor shaft must be in the same parallel. Wood processing requires precision and accuracy, which will be impossible with a poorly fixed base.

When disassembling an old washing machine, there is no need to rush. Carefully remove each of the parts so as not to violate its integrity.

With prolonged contact with water, scale accumulates on the surface.It is dissolved by special means or removed mechanically.

In addition to the motor, a drum, a loading hatch, a body, counterweights and springs are suitable for the manufacture of home-made devices.

The engine will become the basis for a lathe or concrete mixer, and the hatch can replace an ordinary window in a room decorated in a custom style. And this is not all that can be done from an old washing machine.

Simple picking machine for home use

Plucking chickens by hand is long and tiring, and buying a factory-made feathering machine is expensive.

The problem is solved by having an old washing machine, ideally with top loading:

- On the shaft from the machine, we make cuts for the pulley, process the thread.

- We select an adapter from another device, for example, the steering finger of an old UAZ.

- We use the cap from the centrifuge for clamping.

- We assemble the frame on which the engine will be fixed.

- We fix the pump with a reliable adhesive.

- On the reverse side we mount the pulley.

- Check the operation of the belt drive.

- We connect the tachometer, windings from the collector to the anchor.

- We hide the control unit under the tabletop.

- We attach the container for carcasses with rubber “fingers” to self-tapping screws.

- We lay the bottom of the machine up, fix it with a cap.

Consider strong vibration when processing the carcass. An unstable structure will quickly fail.

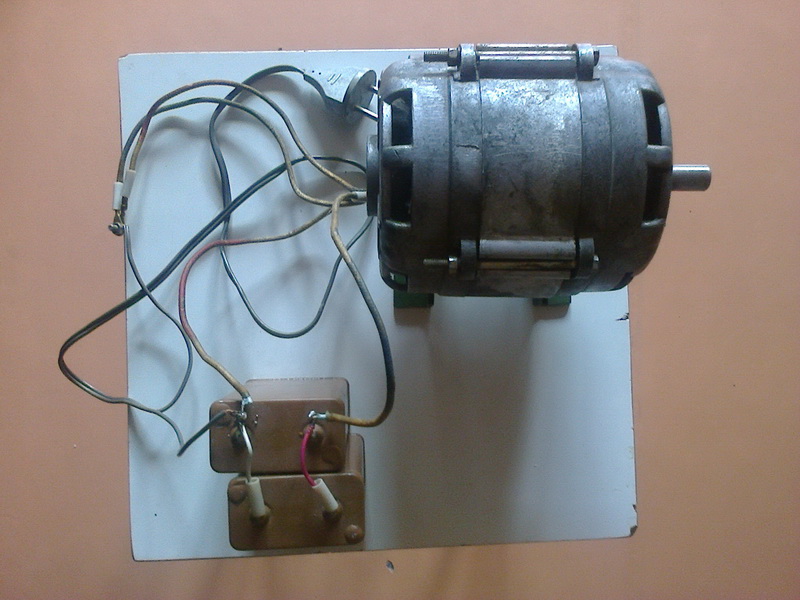

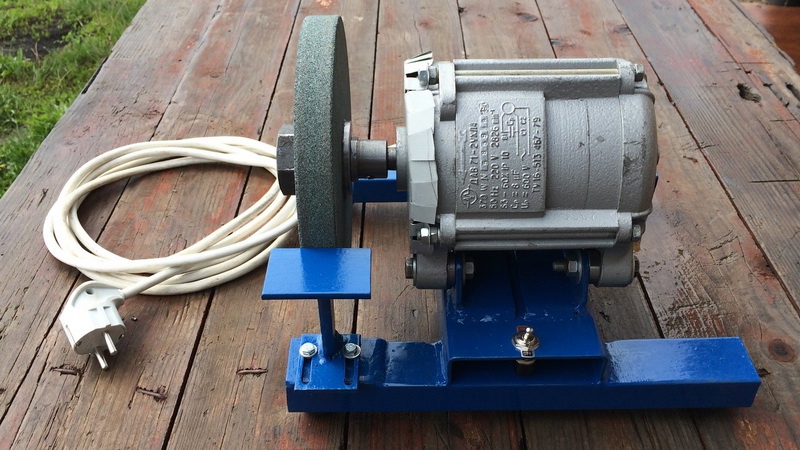

Grinding machine or sharpener

For equipment for sharpening knives, scissors, garden tools, it is not necessary to go to the store. Like a lathe, a grinder is easily made with your own hands from an old motor. A ready-made flange is suitable for fixing the emery wheel - it is easiest to handle.

Among the different types of engines, it is worth giving preference to models of low power.

The grinding wheel is fastened with a washer and a threaded nut, directed in the direction opposite to the rotation of the shaft.

lawn mower

A lawn mower is a homemade product from an engine from a washing machine, in terms of functionality it is in no way inferior to the factory model. In addition to a stable and strong frame, a casing is required here to protect a person from injury and the motor itself from foliage and dirt.

The base can be made from scratch or you can take a frame from a cart, an unnecessary stroller.A sheet of metal is attached to it, then a casing and a special bumper in the front and rear parts.

Before the first start, you must make sure that all elements are isolated and connected correctly.

Animal feed cutter

If you take a drum with the motor, you can make a device for grinding animal feed. A washing machine without a top loader is worse than with it. The body is made of metal sheets.

The walls should not interfere with the free rotation of the blades of the unit. It is worthwhile to provide for a clamp in advance, which is indispensable when working with beets and similar vegetables.

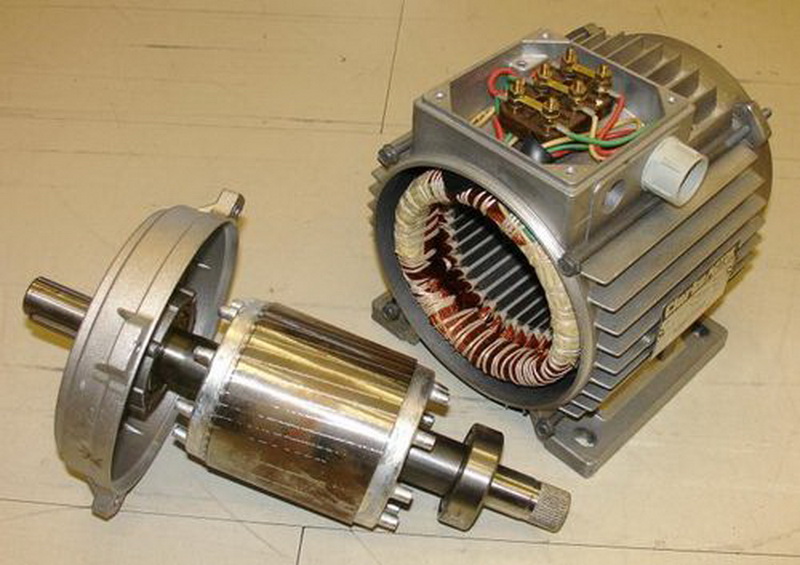

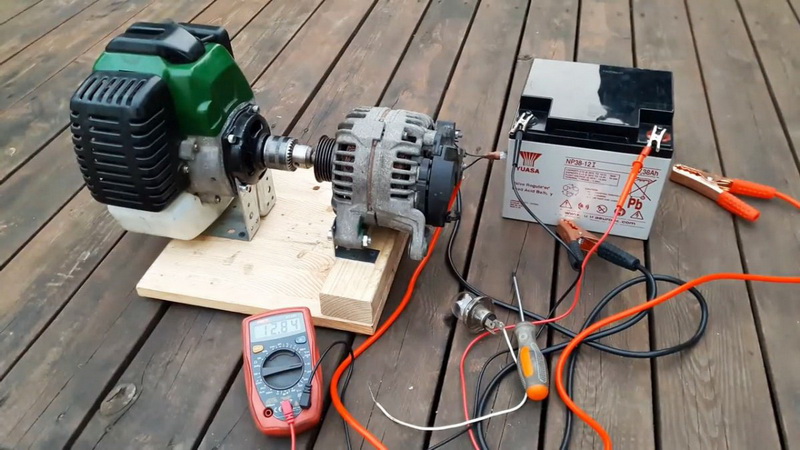

Generator

It is impossible to make a generator based on the engine of a washing machine without a turner. At a minimum, you need to have basic turning skills. On the motor core, grooves are required to fit the purchased neodymium magnets.

For their fixation, tin samples are prepared with dimensions corresponding to the grooves and the core. Magnets are placed at the same distance from each other, attached to the glue.

Concrete mixer

If drain holes are soldered in the drum, it can be used as a container for concrete.In front-loading machines, you will have to redo the minimum, they are in priority.

The solution significantly increases the weight of the structure, so it should be equipped with wheels. A specially designed mechanism is required to rotate the barrel. It can be based on the principle of a bicycle chain.

If the angle of inclination of the barrel is chosen incorrectly, the unit will jam after loading the cement mass.

Useful video tutorials for crafts from an old washing machine: