The tachometer of a washing machine is a small device that is installed on the engine rotor to control its speed. The tachometer is also called the tachogenerator of the washing machine. In some washing machines, such a sensor is called a Hall sensor, it is slightly different, but their principle of operation is exactly the same.

The principle of operation of the tachogenerator in the washing machine

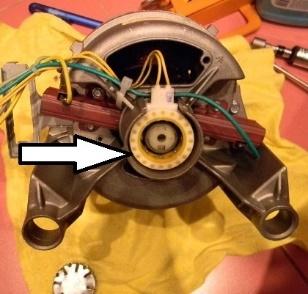

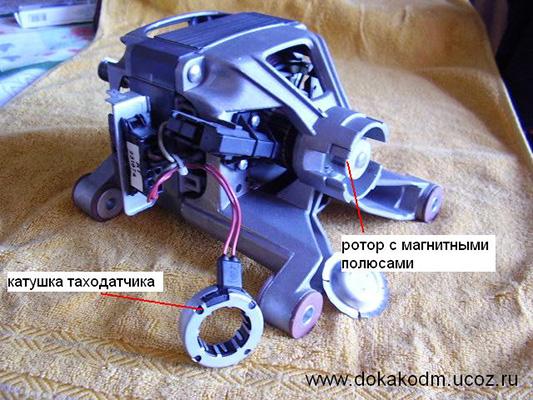

The principle of operation of the tachometer is quite simple. The tachogenerator itself is located on the motor shaft and is a small ring with wires. When the motor rotates in the ring, a voltage is generated due to the magnetic field (generator principle), the higher the speed of rotation of the motor, the higher the voltage. Accordingly, by measuring this voltage, you can get the speed of rotation of the engine.

It is for measuring the speed of rotation of the engine that the tachometer in the washing machine is used. The principle of operation is the following. Suppose the engine spins up and starts to rotate the drum, in order to activate the spin, you need to increase the number of engine revolutions to 800 rpm.The control module gives a signal, gives a command to increase the engine speed, but when do you need to stop raising the speed? For this, a tachogenerator is needed, it constantly gives the parameters of the engine speed and thereby allows the control module to make decisions about the speed of rotation of the motor.

Symptoms of a faulty tachometer

If the tachometer breaks in the washing machine, then it begins to behave as follows.Since the number of revolutions is not controlled, the machine starts to rotate the drum at the wrong speed. During washing, the speed may be too high, and during the spin cycle, on the contrary, the speed does not rise. The machine may not spin the laundry at all. Such "glitches" indicate that one of the reasons for their appearance may be a tachometer.

To check the tachogenerator of the washing machine, you must first get to it.

Where is the tachometer located in the washing machine

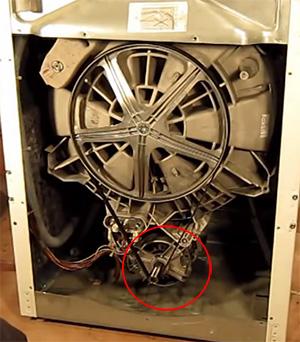

The tachogenerator of the washing machine is located on the motor shaft, which is installed at the bottom of the washer. To get to the engine, you will need to remove the rear wall of the machine. To do this, unscrew the bolts that secure this wall and remove it. The engine is at the bottom and connected with a belt to a pulley, you can see it right away.

The tachometer is located on the rear of the motor on the shaft. To check or replace it, it will be necessary to remove the engine, this procedure is described in detail in do-it-yourself article on repairing a washing machine engine.

How to check the tachometer on a washing machine

To check the tachogenerator, it is optional to remove it from the engine, but the engine itself will have to be removed from the washing machine.First you need take off the belt from the motor shaft. Next, unscrew the bolts securing the motor, pull the motor out, after disconnecting the wires from it.

To check the tachometer for operability, do the following:

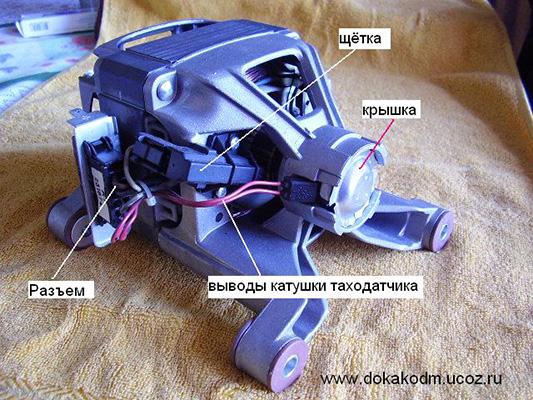

- First, disconnect the tachometer wires from the connector, and then measure the resistance on them. To do this, you will need a multimeter, which must be switched to resistance measurement mode. The normal resistance of the tachogenerator should be around 60 ohms.By the way, you can do this procedure without removing the engine from the washing machine.

- To make sure that the tachogenerator works and produces current when the engine rotates, switch the multimeter to voltage measurement mode. While measuring the voltage at the terminals of the tachometer, turn the engine by hand. The tension must rise. When the motor is rotating, it is usually around 0.2 V.

- If everything is good, check the tachogenerator mounting bolt, very often it relaxes and the sensor starts to “fail”. If he is relaxed, pull him up.

If your tachogenerator did not pass these tests and its fastening bolt was tightened, then it's time to change it. The tachometer breaks most often due to overloading the washing machine.

How to replace a tachometer in a washing machine

First we need to remove the tachometer from the washing machine. To do this, you first need to disconnect the connectors of the tachometer, if you have not already done so. The connectors can either simply be pulled out or be fixed in a common block, from where they must be carefully pulled out. Using a thin slotted screwdriver.

Next, you need to remove the tachometer cover, it usually snaps into place. Lids are either metal or plastic. Also, the cover can go together with the tachogenerator and is fastened with bolts. We unscrew the bolts that secure the tachometer and remove it.

Assembly is in reverse order. In the video below you can see how to remove the motor from the washing machine.

Comments

Thanks for describing the problem! Tilt the machine, and there the sensor fell out! The magnet that is twisted onto the shaft got out and pushed the sensor itself out!

I checked the resistance on the tachometer - 178 ohms.Does that mean he's wrong? (The machine turns on the spin speed at the most inopportune moment, especially often when rinsing, with a full tank of water)

Solved the problem? The situation is one on one. Resistance 178 ohm instead of 60. Is the tachometer defective?

Hello, during the washing process, I get an error le according to the instructions for overloading the engine, can anyone tell me what is the reason? Thanks

“In some washing machines, such a sensor is called a Hall sensor” - In some washing machines, a Hall sensor is used as a tacho sensor

Can the control module fail due to a faulty sensor?

Is it possible to independently change (reflash the sensor / install another one) the maximum spin speed? I have 800 and things take a long time to dry (for example, jeans do not dry out until morning)

Please tell me what is wrong:

one). On spinning more than 500 revolutions, stops and flashes.

2). On spinning, water flows into the tray.

Hello, for what reason can the heating element squeeze out from the washing machine during washing? And it may or may not be.

Another story happened to me: the BOSH WLK242470e washing machine worked fine for about five years and suddenly stopped spinning up to high speeds. That is, while washing is in progress, everything seems to be spinning, washing, and when the spin should start (as when starting the spin program) It starts spinning at low speeds and when trying to spin up to high speeds, it thinks for about three seconds and tries again, it does not go into error, the program time is ticking and now, after 12 minutes, pick up your laundry, and water drips from it.I came to our NORD-SERVICE spare parts store, they say for these machines, instead of a tachometer, the G-sensor costs 3000r and it is not available even in Moscow, it’s better to take the complete engine (17000r) well, I was sad - I came home and dismantled the engine, and there everything covered in brush dust. I cleaned EVERYWHERE, blew it with a compressor, put it back together and voila, everything works, I saved it - it means it worked :). Actually advice - if the hands are attached with the right end to the body and also the head in the right place, then try it yourself and you will succeed.

Washing machine gave an error about the failure. dv. or tachogenerator. I dismantled the tachogenerator, and there on the stator there was a white uniform fine thick ardor, I wiped everything, assembled it, it worked

Stir. the ariston AL 109x machine does not spin the drum during the initial wash, as if there is not enough power, the drum rotates normally during the spin cycle. Could this be from the shaft speed sensor? Fellow "masters" who came to the diagnostics said that the motor is working, the brushes and the belt are in order, the programmer seems to be the same, but why is it not spinning ??? they themselves do not know

The problem is this: it seems to wash normally, but it only comes to rinsing and spinning, the speed explodes to the maximum (the machine bounces) and stops with all the indicators flashing and blocking, it saves the shutdown (button) and 30 min. idle time. I sin on the speed sensor (resistance ~ 180 Ohm). Top loading Candy machine.