Many have probably heard about the so-called inverter washing machines, but no one really knows what it is. Everyone only knows that the inverter motor is better than the usual one and has some advantages over it.

Let's try to figure out what an inverter motor is in a washing machine, whether it is needed at all and how such a washing machine differs from the one in which there is a conventional motor with brushes.

To begin with, we need to understand the principle of operation of the inverter motor.

What is an inverter motor in a washing machine

The principle of operation of the inverter motor is based on the fact that the frequency converter (inverter) controls the speed of the motor. It converts alternating current to direct current, after which it forms an alternating current of the required frequency. This process allows very precisely regulate the speed of rotation of the motor and maintain the desired speed.

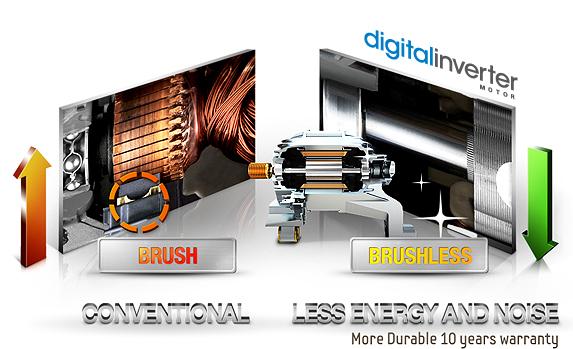

The most important difference between an inverter motor is that it has no rubbing parts (brushes), and the rotor, as in any electric motor, rotates under the influence of an electromagnetic field.

What are the advantages of an inverter motor over a conventional one:

- The absence of rubbing parts allows you to spend less energy on the rotation of the engine, which increases its efficiency and saves you energy.

- Such a motor is more durable and it does not have to change the brushes.

- Less noise during operation, because there are no rubbing parts.

- Provides very accurate maintenance of the set speed and reaches them instantly.

Inverter type washing machines - does it make sense?

Well, we figured out the inverter motor and the principle of its operation, but now let's try to understand whether this technology is needed in a washing machine and whether it is worth overpaying for it, because for many years we have been using ordinary washing machines without these miracle engines and do not experience any problems.

Advantages of an inverter washing machine:

- energy efficiency

- Quieter operation

- Spin at high speeds

- Engine durability

- More precise observance of the number of revolutions

Cons of an inverter washing machine:

- Greater cost than normal

- High cost of parts in case of engine breakdown

The pros and cons are clear, but let's look at them in more detail.

The most indisputable advantage is, of course, energy efficiency. Inverter washing machines consume less electricity than conventional ones. Marketers claim that the savings reach 20%.

More quiet operation, this is, of course, an indisputable advantage, but let's take, for example, LG with direct motor drive technology, direct drive reduces noise much more than an inverter motor in a washing machine.

Spin at high speeds - a good thing, because after it the clothes are almost dry, but spinning at 1600 or 2000 rpm literally tears your clothes, and they go to the landfill much faster. More about washing machine spin classes Learn from the article at the link.

It's nice to understand that the engine will work for a long time and may never break down, but if you take ordinary washing machines, then people operate them for 15-20 years and do not look into the motor. And after how many years will you change the washing machine? Do you need this durability?

RPM accuracy in the washing machine seems to be a very dubious advantage, because it is simply not needed there.The washing machine should just wash well and be able to wring out the laundry, and what difference does it make with what accuracy it will do it.

Should You Buy an Inverter Washing Machine?

You have read about the pros and cons of such washing machines, and now you can decide for yourself whether you need such a washing machine.

We, in turn, would like to say that the fact of the presence of such a motor does not indicate the quality of washing or the presence of any functions in the washing machine. This is not a guarantee that it will last you longer and will save energy better than conventional. Why? Read about washing machine energy consumption and use this information to determine energy efficiency. Undoubtedly, technology such as a brushless motor in a washing machine is a plus, but is it worth it to pay extra just for having it.

Why buy?

Induction motors are used in new generation machines, and if you choose a washing machine with just such an motor, then, best of all, pay attention to the modern features that it is endowed with and decide for yourself whether you need them or not. And the inverter motor will be a nice bonus and nothing more. You should not take a washing machine just because of him.

Given the global trend towards environmental friendliness and energy saving, it would not be superfluous to mention our partners - EcoEuroDom, which specialize in the production and construction of eco-friendly houses from SIP panels. You can get acquainted with the offers and make preliminary calculations on a convenient calculator. link

Comments

Since when have brush motors been used in washing machines? Never heard…

After the first paragraph of the explanation of the essence of the inverter speed controller, the rest of the article is complete nonsense of marketers. The author mixed together a direct drive from the LV company and an inverted speed controller.True, the advantages of the inventory are described correctly, but they also include the features of a direct drive. The inverter is a speed controller that can be screwed to ANY AC motor - an analogue of a rheostat for direct current. And the absence of a belt is the advantage of a direct drive, which can have not only an inverter - that is, smooth adjustment, but also a stepwise one - a pre-set 3-4 number of revolutions, which was in the old LV models.

And as for the low noise level of direct drive, how much lower is it, if, according to the manufacturer's own data, the noise level of direct drive machines can be even 1-2 dB higher than other belt driven machines ???

After reading the article, I also got the impression that the inverter = direct drive.

Almost all washing machines use asynchronous motors. and they don't have brushes. They are started by starting capacitors.

Read carefully gentlemen. The article is written absolutely correctly, technically.

Such an engine would be invented for a drill and other equipment.

for a drill and other equipment, simplicity, dimensions and power are needed. An induction motor drill will be huge, expensive and inconvenient.

Another 50 years and the fire from the lighter will be equated only with a miracle! Now to the point. The usual asynchronous is shown. (The article mixes the concepts of a drive (the motor itself) and a speed controller (inverter). Until the mid-90s, an asynchronous motor was considered a motor of rigid characteristics and had only 1-4 speeds (from the number of pairs of poles pre-wound at the factory, which had a strictly defined speed, for example, 980 rpm or 1480) With the development of electronics, they learned to regulate the speed by reducing or increasing the frequency. By the way, thanks to this, the same engines are now installed on trams and trolleybuses (they are much cheaper).

And finally, direct drive. I didn’t understand the topic exactly, but I can say that the belt smooths out vibrations and dampens vibrations. And here it turns out all this goes directly and as the bearings wear out ....

In short, old technologies under the new noodles of marketers (Do they even remember physics from school?)

And why don’t they write about how bearings fly on direct drives, three years and dosvidos.

I see no reason to criticize the article, especially from a technical point of view, and it’s right about marketing from the point of view of tricks. Nothing is forced. I will add the technical side with some details. The stumbling block is similar in the word "inverter". So, from the point of view of electrical engineering, an inverter is a FREQUENCY CONVERTER of current and (in the same electric circuit) voltage. First of all - frequencies! What is it for.In our country, the standard for the frequency of alternating current at the output of the generators of power plants and then in the outlet is 50 Hz (in the USA 60 Hz). In industry, three-phase BES collector (on the rotor) motors are mainly used. The windings of the three phases in the stator are shifted (stacked) relative to each other by an angle of 120 degrees, when viewed from the end of the stator or the rotor shaft. The voltage peaks in each phase of the industrial current are not simultaneous, but also shifted in time (these are the properties of 3-phase generators). If we conditionally depict the clock dial with arrows, then the peak voltage of phase “A” is at 12-00, phase “B” is at 4-00, and phase “C” is at 8-00. It turns out a rotating voltage peak and, accordingly, the rotation of the induced magnetic field, which drags the stator behind it (in a circle). The phases can be mixed up as you like, only the direction of the magnetic field and, accordingly, the rotation of the motor rotor will change (can).In household sockets, only 1 (one) phase and a rotating magnetic field cannot be created (without a phase splitter), therefore, in household tools, a collector motor is more often used (drills, punchers, grinders, etc.), which can also work from a constant current. In household washing machines, during the USSR, they also used without commutator motors, but NOT asynchronous, but CAPACITOR AC motors, two-phase! The fact is that when a capacitor is connected to an alternating current circuit, it shifts (conventionally according to the watch dial) the voltage peak at an angle of 90 degrees, the winding of the second phase of the stator shifts to the same angle during the manufacture of the washing machine motor, a rotating magnetic field is obtained, although less effective for thrust (in a circle) of the rotor. Such an engine cannot be attached to a drill without a capacitor.At the same time, when using a 3-phase motor in a single-phase (domestic) network, the capacitor can ONLY be used to start the motor, because. in the motor (3-phase) the windings are shifted by 120 degrees, and the capacitor shifts the current only by 90 degrees, the winding in which the capacitor is connected will overheat during prolonged operation and may fail from charring of the insulating varnish of the wire of this winding and, accordingly her k.z. 3-phase AC motors are called so a-synchronous (probably in an asymmetric manner (e)), because their rotor does NOT rotate synchronously with the rotation of the stator magnetic field, but somewhat slower, it lags behind. In a 2-pole (meaning for each individual phase) motor, the rotational frequency of the magnetic field is determined: n \u003d 60 * f: p, where p is the number of pairs of poles (for any one winding), f is the FREQUENCY of the alternating current, here it is and changes - regulates the inverter - frequency converter. Substitute different numbers (and 0 Hz) into the formula and see what happens with the engine rotor speed.Drills with a collector make no difference, there is no and no need for a rotating magnetic field. I'm talking about marketing. And in the collector motor, can you hear the rustling of the brushes on the collector? In transformer substations, nothing rotates at all, they are buzzing! In email engine, first of all, defective bearings, internal air flows, in powerful email will be heard. motors are analogous to transformer hum when they are heavily loaded. So the expression “inverter motor” in itself can only have the meaning that the frequency of rotation of the AC motor is controlled by the inverter, respectively, the washing machine has an inverter for this, which is generally good, washing. the machine is more manageable for each type of fabric, etc.

Here they write that, they say, the article is technically correct ...

But as soon as you read this phrase "and the rotor rotates under the influence of an electronic magnetic field" raises a big question about the professionalism of the author. What is this new kind of field, huh?

The author, apparently, wanted to say “electromagnetic”, but the fact that he is confused in concepts raises great doubts about his professionalism in general ...

What are the fields: https://ru.wikipedia.org/wiki/%D0%9F%D0%BE%D0%BB%D0%B5_(%D1%84%D0%B8%D0%B7%D0%B8%D0%BA% D0%B0)

Almost everything is written correctly, but not all single-phase asynchronous motors are capacitors. I am a witness to the fact that washing machines were equipped with motors with starting windings and centrifugal switches and no capacitors. I still have such an engine on an emery machine!

Inverter motor = capstan. The standard one consists of 3 stator windings (or more, a multiple of 3) and an anchored permanent magnet. Hall sensors are installed on the stator for precise phase control. The inverter alternately switches the windings. The higher the switching frequency, the higher the speed.The author correctly wrote that the DC motor. Direct drive is a particular example of such an engine. Inverter systems have long been used in cars. The blower fan, stove motor, electric rail, various pumps built on this principle have been working remarkably well for many years.

read the reviews and want to study electrical engineering. about washing machines with a direct one, and even with an inverter motor, it’s not at all interesting.))))

The trouble is that most often the water pump dies, not the engine ... So for me personally, a regular engine is fine!

No washer - no problem! I've got a gas cutter covered, yes ....)))

I’ll put in my five cents. Current switching to the motor windings is carried out by an electronic unit (inverter). It consists of a large number of transistors, thyristors, microcircuits, etc. This reduces reliability and dramatically increases the complexity and cost of repairs. This is not a replacement for a bearing. And You will have to turn not to Uncle Vasya, but to a service center, which is what the seller needs. And after the gas cutter, you need to spread fuel oil on bread!

Each article on the site is stupidly paid for by LG and a little Bosh .., which is why I won’t take either technique! So, if a manufacturer descends to such baseness, then it means that it is really worse, as many people write in the comments!

1. I am sure to put on or change the belt at times cheaper and easier and more than pressed bearings in a non-separable drive with a tank, while being killed many times faster with direct drive.

2. The noise level is prescribed in the passport and during the spin cycle (the most noisy process) it is approximately the same for all models (I did not consider models at the price of a used car) with direct and belt drive, an inverter or a standard engine, this is 70 dB +/-10 %.

3.Energy savings average 0.05-0.1 kW / h per wash cycle, and the cost of a washing machine with an inverter is on average 1/4-1/3 more expensive than a machine with a simple engine. The cost of electricity, of course, is different everywhere, but with our prices and the frequency of washing (my mother is alone, she washes a maximum of 2 times a week), this difference will be beaten off from her only after 288 years! 288 years Carl!!! )))

four.A 10-year warranty is certainly good, but I think after 5 years it will be necessary to change the machine, as iot, smart home, integration with mobile phones, etc. will develop, and with the current quality, by 5 years I’m afraid it will survive 1-2 repairs ... And there you will have to take the next one (((

- I summarize my choice: a simple engine with the necessary functions for us cars. The 86th Ariston has been working for 15 years, but we will leave it in the old apartment for rent, and I will take a new washer to my mother’s new hut.

Which one will you take?

Advertising is a mixture of rational and irrational or truth and fiction, but the goal is the same - manipulation of the minds of consumers. A specialist article is no exception. The naive may believe in the ability of marketers to evaluate the efficiency of engines, in the professionalism of engineers writing about the instantaneous set of the desired speed and the presence of various types of drive in electric motors.

Russians have been bred since 1991! Like hamsters!

You have never heard of BUBBLE flotation washers!

And they are sold all over the world.

You get a regular BRUSHLESS motor as the latest invention, and you are happy!

And they make it for you using cheap technology - outdated - anyway, buy it like cars that have not been allowed on the German market for a long time, only they make relatives for you!

The old rule: the simpler the mechanism, the more reliable.The first mobile phones worked for years without problems. Now grandparents already have smartphones and “fly” in 2-3 years. But technological progress continues and we have to keep up with it.

Bosch