Automatic washing machines are a fairly reliable type of equipment today, and if breakdowns occur in them, they are usually fixed. One of the most difficult and costly breakdowns to repair is bearing wear in a washing machine. If the bearing is worn out, it needs to be replaced. As a rule, such a complex repair is trusted to professionals, because in order to carry it out on your own, you need to have the necessary skills and tools.

If you still decide change the bearing in the washing machine with your own hands, you will encounter a bearing seal in the washing machine, which requires the necessary lubrication. Here we will deal with this issue and tell you how to lubricate the oil seal in the washing machine.

What is an oil seal in a washing machine

An oil seal is a rubber sealing ring that is needed to seal gaps between static and moving parts. In our case, the gland is a rubber ring that prevents water from flowing out of the washing machine tank through the gaps between the tank and the shaft.

As you can see from the photo above, the oil seal is inserted onto the bearings, and inside it has a hole for the shaft. As you already understood, during rotation, the shaft constantly rubs against the walls of the stuffing box, thereby wearing it out. Therefore, the oil seal must be well lubricated in order to last longer.

What happens if you do not lubricate the oil seal in the washing machine

If you changed the bearing and forgot to lubricate the oil seal, which is unacceptable, then you may experience the following problems: the oil seal will wear out very quickly, it will not last long, working “dry”, after which it will begin to let water through. Water will enter the bearings, which will also rust very quickly and their frictional force will increase. You will need to change them again along with the oil seal. Therefore, you be sure to take care of the grease for the seals of washing machines and buy it in advance, before the start of the repair.

What are the requirements for lubrication for oil seals

Of course, there are those who will say that oil seals can be lubricated even with sunflower oil, but for them we have serious arguments why this should not be done.

- Grease for oil seals must be moisture resistant. This is necessary so that it does not wash out with water over time.

- The lubricant should not be aggressive and "corrode" or soften the rubber. If you lubricate the oil seal with a grease that is not intended for this, then it can shorten its service life.

- Heat resistance - since during the operation of the washing machine, the shaft is constantly rubbing against the oil seal, as well as the operation of the bearings, then they heat up. Also, when washing in hot water, there is a temperature effect on the lubricant, so the lubricant should not lose its properties when the temperature changes.

- The consistency of the grease should be thickso that it does not leak out during long work.

As you can see, oil seal lubrication must be taken seriously, because the “wrong” lubrication can ruin all your bearing replacement work and hasten a new similar repair.

Choosing a grease for a washing machine oil seal

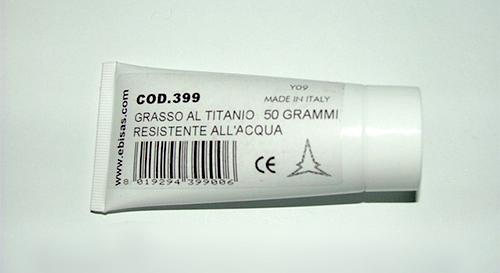

You can buy special grease in specialized stores that sell spare parts for washing machines. If you tell the seller why you need lubrication, then for sure he will give you a suitable tube without any questions.The only problem is that such a lubricant will be expensive, because it is believed that it is specially designed for this purpose.

Of course, you can try to save money and find cheaper analogues. Silicone grease is considered a good lubricant for oil seals., it meets all the requirements, and most importantly has good moisture resistance.

When buying silicone grease, pay attention that it is moisture and heat resistant, and also thick. Usually these parameters are indicated on the tubes: moisture resistant, maximum operating temperatures.

One excellent silicone oil seal lubricant is LIQUI MOLY "Silicon-Fett"which meets all requirements. Of course, it is also not cheap, but the quality is at its best. She can safely lubricate the oil seal in the washing machine. Its operating temperature ranges from -40°C to +200°C.

How to lubricate the oil seal of a washing machine

You changed the bearings and now you need to insert the oil seal, but before that it needs to be lubricated. To do this, take a lubricant and apply it along the outer contour of the gland with a thin layerspread evenly.

After that, we insert the gland into a niche in the tank. Farther lubricate the seal along the inner contour.

All! This completes the lubrication of the oil seal. Now you can continue to assemble the washing machine.

Comments

I would like to know what Little did not please?!?!? This is a moisture-resistant lubricant operating at temperatures from -40 to + 120 degrees Celsius.