Have you noticed that your washing machine has stopped heating water during washing? This indicates that there was a breakdown of the heating element.

You can call a repairman, he will replace the spare part, or you can do this work yourself, because it is not as difficult as it seems at first. Moreover, it will save several thousand of the family budget.

How is the heating element replaced in the LG washing machine? We invite you to learn more about this procedure.

Repair: what you need

Phillips and flat screwdrivers, suitable diameter. Grease, WD-40 will do. Tester. Ratchet with socket head for 8.

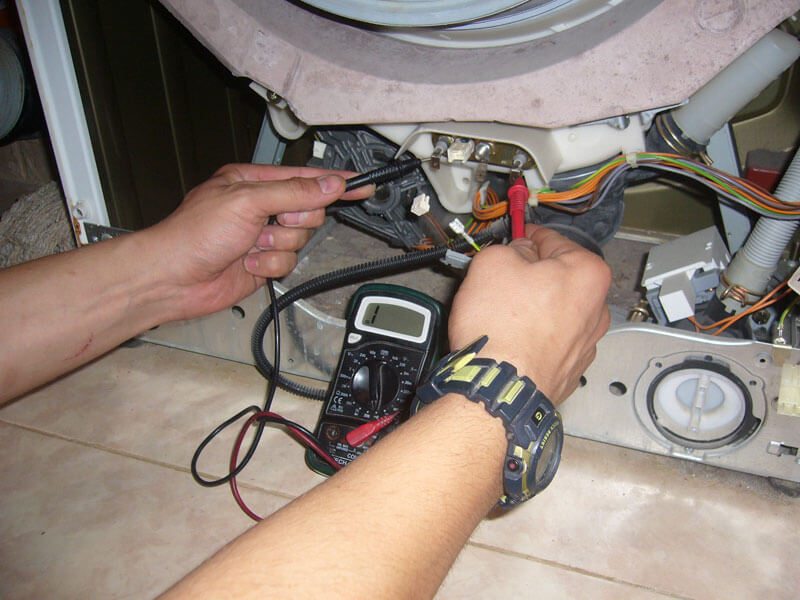

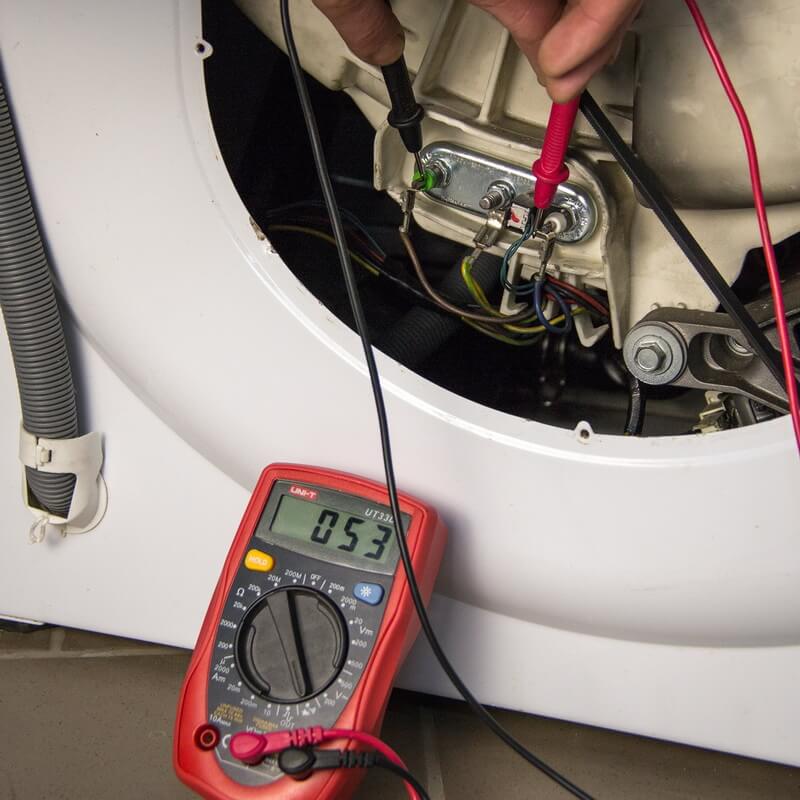

Before you decide to start replacing the spiral, we advise you to check its serviceability, the problem may be in the breakdown of the electrical circuit itself. How to check the heating element of a washing machine? For this, a standard tester is enough. The test is based on three main parameters.

Spiral breakage is the most common cause of breakage. The part is called by attaching the tester wires to the terminals. If the meter needle sharply deviates to 0 in resistance mode, this means that the coil has burned out.

A hole in the body of the heating element. A rather dangerous cause of failure for machines without grounding.The current will go directly to the case and you can get a noticeable electric shock. The coil breakdown test is checked after the element has been heated for a short time.Deviations of the arrow on the measuring scale of the tester indicate the presence of a breakdown.

We change ten

Consider the process step by step using the example of a front-loading machine. So, how to remove the ten on the lg washing machine:

- To begin with, the water from the drum of the machine is completely drained. On the front panel at the bottom, either in the middle or on the side, open the cover. Under it you will find a valve. Unscrew the cover until the plug is completely removed. Lay an unnecessary rag on the floor or place a water container. Do not tilt the body of the machine in an attempt to speed up the draining of water - weights may damage the body.

- Position the machine so that you have easy access to the rear panel. We unscrew the bolts fixing the wall.

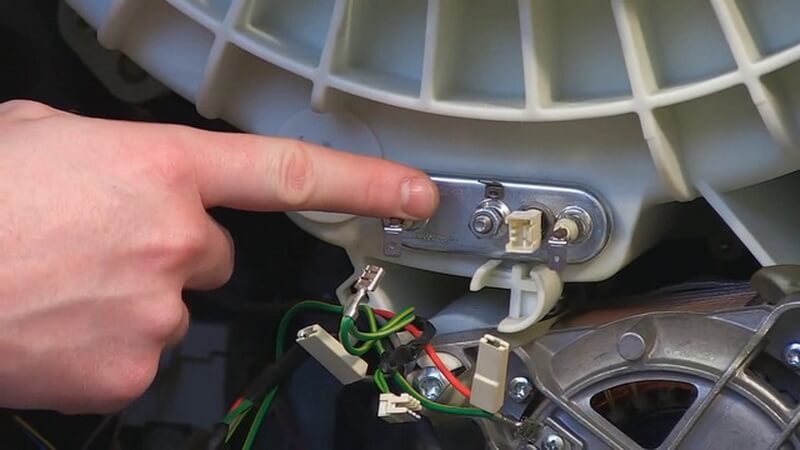

- The heating element screwed to the bottom of the drum has three clamps. The temperature sensors that the machine is equipped with often react to blows with a breakdown, this must be taken into account and try to knock on the machine as little as possible.

- We remove the zero and phase terminals, unscrew the nut, with which the ground is fixed, remove the connected contacts

- The lock nut of the ground screw is unscrewed a little, by the length of the thread. This technique will help to avoid jamming during tapping when removing the heating coil.

- The body is gently pushed through with the edge of a screwdriver, slowly opening it, try not to jam the heater seats while pulling it out

- Before repair, you need to purchase a new part to replace it. When buying, experts advise taking the old one with you, this guarantees the correct choice.

- Before installing a new part, thoroughly clean the installation site. For this procedure, the means and methods convenient for you are suitable. The quality of cleaning is checked by a bright beam of light from a flashlight.

- Check the seats and sealing gum for deposits.

- After loosening the ground nut, insert a new coil.Pay attention that the element would clearly stand in the niche intended for it.

- After tightening the nut, we reconnect all the wires to the terminals.

To check the repair, a little cold water is poured into the drum of the machine, the heating is turned on for a short period of time.

After turning off the heating, the water is warm and there are no smudges? So everything is done correctly and you can close the back panel of the machine, fixing it with bolts.

Causes of failure of the heating element

Power surges in the network

During worsening weather conditions or breakdowns, voltage drops can occur on power lines. From an increase in voltage from 220 to 380v, automation and spare parts can burn out.

Poor water quality

Hard water with a high calcium content builds up deposits on the heating element during operation. Such deposits impair the efficiency of the element and cause subsequent failure of the heating coil.

Signs of a broken heating element

- A sharp deterioration in the quality of washing. Selecting a higher temperature setting and adding other detergents does not help.

- Reducing electricity consumption on the one hand is certainly a pleasant moment, but it can mean a breakdown. Heating water with a washing machine takes up to 80 percent of consumption.

- Spontaneous shutdown of equipment when heating water, the inclusion of a protective sensor and the appearance of an error message on the display.In this situation, the equipment is disconnected from the network, it cannot be used until repaired.