The engine in the washing machine is responsible for rotating the drum, if it is broken, then your washing machine is useless and until you replace it, it will stand dead weight. But there may be several reasons why the drum does not spin, and not only the engine can be to blame for this, therefore, as the last one to send to a landfill, you must first check it. Now we will check the engine of the washing machine, and after a malfunction is detected, you will already know whether it can be repaired or not.

Checking a direct drive or asynchronous motor

An asynchronous motor, like the motor used in direct-drive washing machines, is unlikely to be tested at home. All you can do is check the integrity of the rotor phase windings. But in such motors, the part that breaks most often is the Hall sensor, which is best checked by replacing it with a known working one.

Induction motors are usually very reliable and rarely fail when used properly.

Checking the commutator motor of the washing machine

The commutator motor is the most common unit that is used in most washing machines. We will analyze it in detail.Its best test is to remove the motor and connect it directly to a 220 V network.

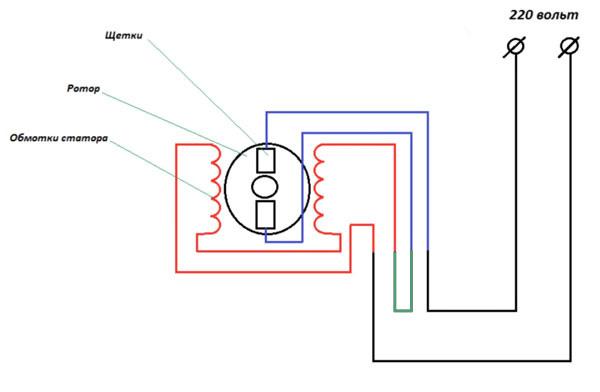

We will assume that you have already removed the engine and are ready to check it. In order to check the washing machine motor for operability, connect it to 220V according to the following scheme:

The connection principle is as follows: the rotor and stator windings are connected in series, the remaining ends must be connected to a 220V network, to change the rotation, the ends of the winding connection change, to learn more about this, read our article on how to connect the electric motor of the washing machine to 220V. If you connected and the motor rotates, and everything is fine when changing the polarity, then we can say that the motor is not quite dead yet, but its 100% performance cannot be guaranteed, because in real work everything happens under load.

Checking the brushes

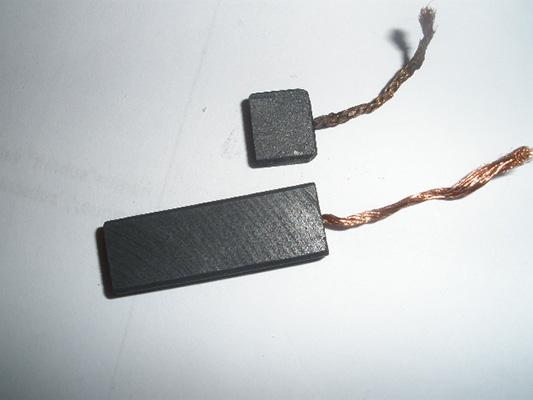

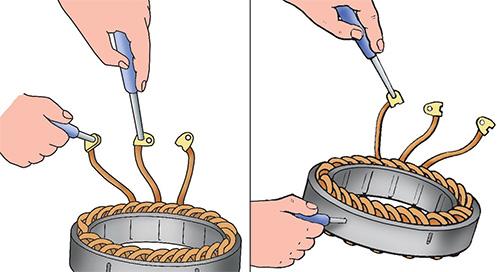

The first step is to check the brushes.. Washing machine brushes - these are graphite "cubes" with wires that constantly, during rotation, rub against the collector and wear out.

If your washing machine has been running for many years, chances are it's time to change the brushes. Look at them, outwardly they should be intact, they should not be chipped. The brush should be long. Look at the image below how the new brush looks like and the already demolished one:

If the brushes are already worn out, they should be replaced. And in general, if your machine is no longer new and you have climbed into the engine, then it is better to replace it immediately and not wait until the brushes are completely worn out.

With worn brushes the machine can turn the drum badly, or stop rotating it altogether. Also, the engine will spark at the junction of the brushes with the commutator.

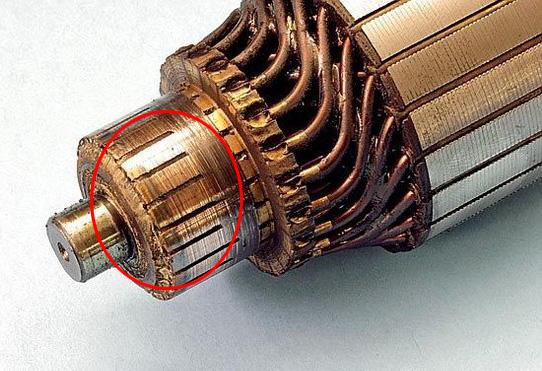

Lamella breakage

Another trouble that can happen with a collector motor is the breakdown of the lamellae. Lamels are such small plates on which the brushes “glide”. The plates are connected to the rotor windings and thus electricity is transmitted through the brushes through them. The lamellas themselves are not very subject to wear, they are glued to the shaft and can peel off in some cases.

The reason why the lamellas can peel off - This is engine jamming.Due to the fact that the machine is operated incorrectly or there are bearing failures, the motor rotor can wedge, and the current on the lamellas increases greatly. As a result, the lamellas can peel off. If the delamination is small, within half a millimeter, then the situation can be corrected by turning the collector.

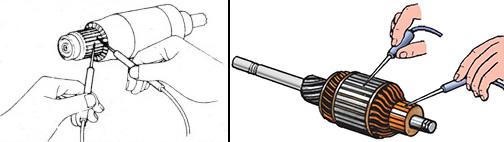

In order to grind the collector at home, you will need a fine sandpaper, with it you need to grind the lamellas, and then it is good to clean all the space between them from the chips that have fallen.

Below in the video you can see how to machine a collector, a machine is used for this, but the principle is the same.

More frequent lamella breakage that can occur is breakage of the rotor wiring from the lamella at the junctionif you have such a situation, then a soldering iron will help you.

Short circuit or break in the wiring of the rotor or stator

This is probably the worst failure that can happen. To check the washing machine motor for an open or shorted rotor windingyou will need a multimeter:

Turn on the multimeter in the resistance measurement mode and measure the resistance between all adjacent lamellas - it should be equal everywhere within 20-200 ohms. If there is a break, then the resistance will be maximum.With an interturn circuit, the total resistance of the winding will be less.

To check the short circuit of the rotor to the iron package, switch the multimeter to the buzzer mode and connect one end to the iron of the rotor, and move the other one alternately along the lamellae, the multimeter should not emit a signal.

Now you need check stator windingand for the presence of an interturn circuit, for this, also with a multimeter in the buzzer mode, close all the ends of the wiring alternately among themselves, the multimeter should be silent. If you saw and heard the signal of the multimeter, then you have an inter-turn circuit.

After that, to check the breakdown of the wiring to the case, short one end of the multimeter to the case, and short the other end alternately to the wiring, there should be no signal. If it is, then the insulation of the wiring is broken and it is punched into the case. In this case the washing machine can be electrocuted.

Comments

Thanks for the good advice, a very useful article. I had brushes working on the washer, I removed it from another engine and put it on

Thanks

Stator windings are checked for housing with a megohmmeter

rotary too.

In general, a washing machine with a collector engine is a budget shit.