Strong noise during operation of the washing machine can occur both for technical reasons and as a result of incorrect operation of the device.

Any unnatural hum, noise, tapping, unusual sound - a sign of a malfunction.

But you should not immediately run to the service center and pay a lot of money for diagnostics, first try to figure it out on your own.

There can be several reasons for noise or unnatural sounds:

- wear or failure of the bearing;

- engine problems;

- during the installation of equipment, they forgot to unscrew the transport bolts;

- a foreign object has fallen between the drum and the tank;

- loose pulley;

- the counterweight loosened or crumbled.

Some causes can be eliminated on their own, thereby saving a lot of money on repairing the device.

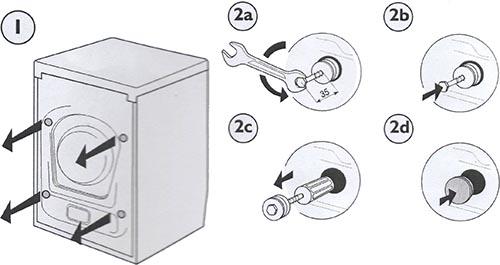

Shipping bolts not removed

Most often this occurs when you install a washing machine yourself. Newly made owners either forget about the transport device or, in general, are not aware of its existence. If you bought a new washing machine, installed it, and it immediately starts to make a lot of noise and vibrate during the spin cycle, then your problem is shipping bolts.

The solution to this problem is very simple - you need to move the automatic machine and unscrew the transport bolts.

Bearing problems

The most important element in the washing machine is the bearing. Thanks to him, the drum rotates, and damage to this part threatens to jam the drum and damage most of the elements in the apparatus. A hum and strong vibration during spinning can occur when washing machine drum loose.

In the early stages of bearing wear, the washing machine hums when spinning, but not too much.. Vibrations may or may not be present. It is extremely difficult to determine such a breakdown, only by disassembling the equipment and looking at the bearing itself.

The bearing breaks very rarely. Most often this is due to corrosion of the metal or wear of the stuffing box. Replacing a node is a rather laborious task that requires knowledge and skills in working with such equipment, so it is recommended to contact specialized workshops. Also, disassembly and replacement vary depending on the model of the device. Typically, a bearing lasts about 10 years.

Relaxed drum pulley

Usually, the pulley problem is detected quite simply - during the spin cycle, audible clicks appear. To tension the pulley, you need to pull out the machine (after disconnecting it from the mains), then remove the back cover. After that, tighten all the bolts on the pulley.

Faulty engine

Such a breakdown is the easiest to determine.If the machine stops spinning the drum, but only buzzes, then most likely the engine has failed (in rare cases it may be a bearing).

In most cases, the problem is solved by replacing the brushes. on the electric motor, but in separate ones - the motor winding may be damaged. In the latter case, it is easier to buy new equipment, since repairs can result in a round sum.

A foreign object has fallen between the drum and the tank

Due to inattention or incorrect loading, various objects (changes, buttons) can get into the space between the tank and the drum, which become a source of unpleasant noise. If the item is not removed in time, this can lead to serious damage.

Removing "foreign bodies" from the washing machine is sometimes very difficult. Sometimes you have to completely disassemble it to get a small coin out. or carnations, so be careful.

Counterweight Problems

The counterweight is used to dampen vibrations during spinning. This element is usually made of concrete. Since the latter tends to age and collapse, it simply begins to hang out on the mount. Symptoms of problems in the counterweight are the hum and strong vibration of the machine. To check its serviceability, you will have to disassemble the machine and check the mount manually. If the counterweight dangles, you can tighten the bolts and it will work again in the correct mode.. In case of severe wear of the element, it is better to replace it.

Finally

Remember, it’s better to listen to your washing machine once again and respond to a possible problem in time than to bite your elbows later when buying a new device. In advanced cases, the device may not be repairable.Recall that on our website we have posted for you reviews containing error codes for washing machines and their decoding, for example, "Errors washing machine Atlant" or Bosch washing machine errors.

Comments

Great article and video