A washing machine is a rather complex device, the heart of which is the engine. The latter serves to ensure the rotation of the drum and is an electrical device.

The motor in the washer does not differ from other asynchronous electric motors and has brushes in its design.

What are brushes for?

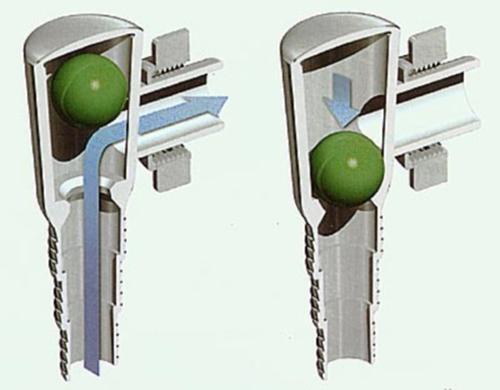

The brushes are a small piece consisting of a cylinder or parallelepiped tip, a soft long spring and a contact. Brushes provide power transmission to the motor rotor windings, thereby causing it to rotate.

Since they are closely adjacent to the axis of the rotor, and the latter, in turn, rotates, it is common for the brushes to wear out over time. These elements are specially made from softer conductive materials so as not to damage the armature elements, because the brushes are much easier to replace than the "heart" of the engine.

Types of brushes

The main difference is the clamping element:

- copper graphite;

- carbon-graphite;

- electrographite.

The spring in all brushes is usually steel, and the contact is copper.

How long do brushes last?

The term largely depends on the frequency of washing, the load on the drum, the correct use of the apparatus, and the quality of the assembly. Usually, This element is quite durable and can work for more than 5 years.. In some cases, brushes for electric motors of washing machines can last more than 10 years. Their replacement is far from always required, since most often something solid fails and you have to buy a new washer.

When should brushes be changed?

It is not difficult to recognize when the graphite rods are worn out, you can determine this by the following signs:

- The electric motor suddenly stopped working. If there were no voltage drops, mechanical shocks against the washing machine, then most likely the brushes simply wore out in the engine.

- An unpleasant noise or crackling may occur during operation of the machine. Most likely, the graphite elements are completely worn out and the springs are already rubbing against the rotor, which is why a crack appears.

- Power drop in the motor. For example, the machine does not gain momentum during the spin cycle and the laundry remains wet.

- From the apparatus begins to bear burning and scorched.

- The device displays the corresponding error code on the display.

How to choose brushes?

Buying brushes for a washing machine is a simple matter, but you need to know a few nuances:

- as a rule, the device uses 2 elements;

- both brushes must be the same, since the installation of elements with different spring stiffness or made of unequal material threatens to quickly damage the engine;

- buy brushes for the engine model that is installed in your washer;

- check parts for defects.

Self-replacement of brushes

Changing brushes is a simple matter, but you need to approach it with the utmost responsibility. For repair work, you will need tools: screwdrivers of different sizes, sandpaper and pliers.

Preliminary disassembly

The steps for disassembling the washing machine are as follows:

- Be sure to unplug the appliance first.

- You need the back of the machine. If you can’t get close to it without disconnecting from the water supply and sewerage, then communications must be turned off..

- Remove the back wall in the car. As a rule, it is fixed on self-tapping screws.

- After dismantling the protective cover, a pulley with a tensioned belt will appear in front of you. You need to remove the belt. This is done very simply: the belt needs to be slightly pulled over and the pulley turned.

- The next step is to turn off the engine from the power supply. To do this, just pull the connector with wires from the socket in the electric motor.

- Remove the engine itself. As a rule, it is mounted on several bolts.

Direct replacement

The replacement of brushes is as follows:

- lay the engine on its side where the brush body is located, unscrew the fixing bolts;

- disconnect the brushes from the motor;

- dismantle the spare part on the other side of the motor;

- inspect the elements - the used ones usually have a rod length of less than 1.5 centimeters (if the length is longer, then the problem is most likely not in the brushes);

- clean the engine manifold, as it will be covered in black dust from the brushes (if scratches are visible, they should be cleaned with sandpaper);

- Install new brushes and secure with screws.

Shutdown

The last step is to mount the engine and return the machine to its place. All actions are performed in reverse order:

- install the engine in its place and secure with bolts or other fasteners;

- connect power wires;

- put on the belt - first on the motor, then on the pulley, scrolling the latter until the belt falls into place;

- mount the back cover.

After completing all work, be sure to check the device. Run any program and listen to the operation of the electric motor. If it works as usual or a little louder, then you did everything right.Rattle, crackle, loud noise are signs of a malfunction.

Conclusion

Replacing brushes is an easy repair, so it is estimated by service centers quite cheaply. To avoid unnecessary trouble, we recommend contacting specialized centers for such work, it may be much cheaper than a mistake when replacing it yourself.

On our site you will find reviews on error codes for washing machines of different brands, for example, Whirlpool Washing Machine Codes or "Hans Washing Machine Codes", which will help you learn how to diagnose and fix some problems in a timely manner.