Self-diagnosis systems are present in almost all modern washing machines. The results of their activities are displayed on indicators and liquid crystal displays, after which we can only decipher the information received.

Knowing the error codes for Hans washing machines, we can quickly identify and even fix some faults ourselves. True, only a trip to the service center will save you from some errors and breakdowns.

You will find Hansa washing machine errors in the table presented in our review. And since there are two series of machines, there will be the same number of tables. The principle here is the same as LG washing machine error codes.

Table of error codes for washing machines Hansa PC series

| The code | Description of the problem | Possible causes |

| E01 | There is no signal to turn on the lock of the loading hatch |

|

| E02 | Long filling of the tank (more than two minutes) |

|

| E03 | Long tank drain (more than one and a half minutes) |

|

| E04 | The pressure switch reports the overflow of the tank |

|

| E05 | Long filling of the tank (more than ten minutes) |

|

| E06 | No signal "Empty tank" from the pressure switch 10 minutes after the start of draining |

|

| E07 | The AquaStop sensor in the sump has tripped |

|

| E08 | Wrong mains voltage | The voltage and frequency of the alternating current in the mains are checked. |

| E09 | High level of foam during the spin cycle | It is necessary to adjust the dose of washing powder. |

| E11 | The triac power supply of the loading hatch lock does not work |

|

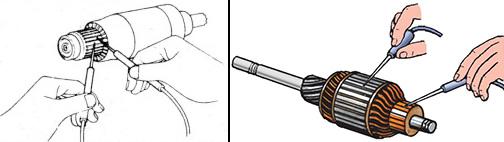

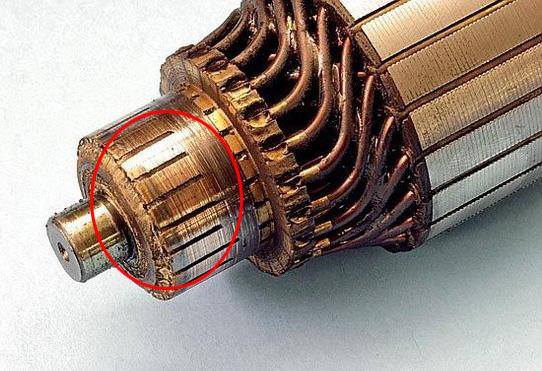

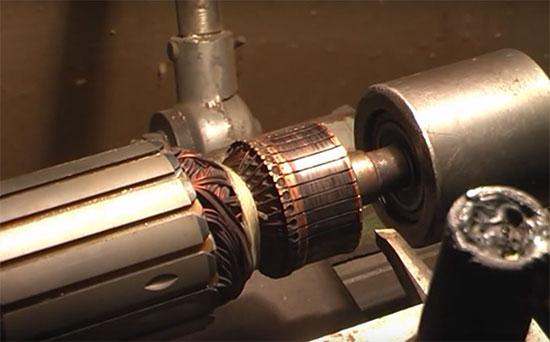

| E21 | Drive motor blocked - no signal from tachogenerator |

|

| E22 | Rotation of the drive motor in the absence of commands | The triac of the drive motor has shorted, it needs to be replaced. |

| E31 | Temperature sensor short circuit | The electrical circuit of the temperature sensor is checked. |

| E32 | Open temperature sensor circuit | The electrical circuit of the temperature sensor is checked. |

| E42 | The hatch door remains locked for more than two minutes | The triac of the lock is checked, the lock itself is checked. |

| E52 | Non-volatile memory failure | Damage to the memory chip on the electronic controller. Repair is done by replacing the microcircuit or the controller itself. |

Table of error codes for Hansa PA series washing machines

| The code | Description of the problem | Possible causes |

| E01 | The door lock switch does not work. The error is displayed for 10 seconds, the current program is interrupted |

|

| E01 | The loading hatch is not blocked. The error is displayed for 2 seconds, the current program is interrupted |

|

| E02 | No signal from the first level sensor for three minutes. 7 minutes after filling the tank, the program is interrupted |

|

| E03 | In the process of draining, the pressure switch does not generate a notification about the lack of water in the tank of the machine (3 minutes after the start of draining). The loading door is blocked until the machine is turned off |

|

| E04 | During the washing process, the pressure switch informs about the overflow of the machine tank, then the drain pump turns on. 2 minutes after the water is removed from the tank, the drain pump turns off. The loading door is blocked until the machine is turned off |

|

| E05 | Open or shorted temperature sensor. Further washing is carried out without heating | The temperature sensor, its circuits and the controller are checked. |

| -||- | Long-term heating of water in the tank (less than +4 degrees in 10 minutes, further work is carried out without heating the water) | Malfunction of the heating element, low voltage of the mains. |

| -||- | The water in the tank does not heat up to the set temperature in the allotted time (further work is carried out without heating the water) | Faulty heating element, low supply voltage. |

| E07 | There is no TG signal from the tachogenerator in the washing mode. After three attempts to start the engine at a speed of 120 rpm, the program is interrupted. |

|

| E08 | There is no signal from the tachogenerator when spinning. The engine stops under the following conditions:

After three overclocking attempts, the program execution stops. |

|

| E10 | Incorrect mains voltage or frequency at any stage of the washing program. If an error occurs, the program is terminated. | The network settings are being checked. |

| E11 | Short circuit or breakdown of the motor triac. After three overclocking attempts, the program execution is interrupted. | The motor and triac are checked. |

| E12 | There was a signal about the presence of water in the pan from the AquaStop system. The washing is interrupted, the water is drained, 2 minutes after receiving an empty tank signal from the pressure switch, the loading hatch is unlocked. | The AquaStop system and its circuits are checked, the cause of the water leak is established. |

| E14 | Control module failure, program aborted. |

|

| E15 | Controller error 3 seconds after pressing the start button, after turning on the machine or selecting a program. | The controller is being replaced. |

As we see, all error codes are clear enough. It is very easy to diagnose a malfunction - we read the error code from the washing machine, find it in one of the two tables, and in the last column we read the list of work required to be carried out. Also easy to diagnose Indesit washing machine errors.