A down jacket is one of the most common types of outerwear in our time. It has very good thermal insulation, is comfortable and practical to wear, and is also affordable. But, like any other thing, in order to stay in good condition, it requires timely care and washing.

But how to wash a down jacket in a washing machine so that the fluff does not stray, and in general is it possible to wash a down jacket in a washing machine and how to wash it? We will answer these and other questions in this article and analyze all the details of washing downy things.

Is it possible to wash a down jacket in a washing machine

If you conduct a survey among the population, asking people this question, then there will be a large percentage of those who will answer that the down jacket is not intended for washing in a washing machine. In fact, each of you can find the answer to this question, and it will be 100% correct. To do this, you just need to look at label with icons your down jacket, where all the requirements for washing it are indicated. And, if you do not see the icon that allows only hand washing, then this means that the item can be washed in the washing machine.

In most cases, a down jacket, of course, can be washed in the washer, but observing all the necessary rules that will prevent unpleasant consequences after washing, such as: knocked down fluff, an unpleasant smell and stains all over the surface of the jacket.

Preparing a down jacket for washing

Before proceeding directly to washing the down jacket, you need to prepare it, because its condition after washing will depend on it.

First, check all pockets for the presence of things in them. If there are any, then you need to remove them.

After that, inspect the down jacket for stains on it.Very often down jackets, especially light ones, get dirty in the area of the collar, pockets and cuffs. If stains are present, they must be further processed before washing.. To do this, rub these places with laundry soap or a special tool.

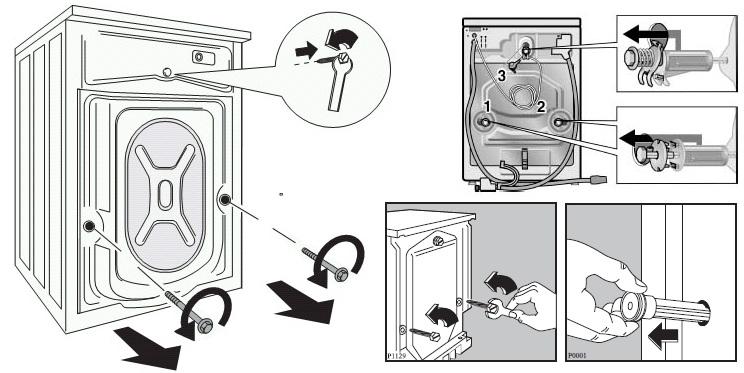

Next you need turn the jacket inside out and leave it like this for the duration of the wash. Wherein fasten all buttons and zippers: nothing should hang out.

You can only wash down jackets in a washing machine one at a time, do not try to push two or more down jackets in one wash - this, at best, will not wash both things normally, and at worst will ruin them.

Washing a down jacket in a washing machine

After the thing is prepared, you can go directly to the washing process itself. For this you will need special detergent for washing down jackets, which you can buy in retail chains or in a specialized store.

It is also very desirable to use when washing such a thing. special balls for washing down jackets or tennis balls, which will not allow fluff to go astray, however, you can read more about this on our website. The same balls are used for washing the sleeping bag in the washing machine, the filling of which is fluff.

Next, we need to decide on which program to wash the down jacket in the machine. If your washer has a special program for washing down jackets, then you will not have to think about these issues for a long time. If you didn’t have such a program, then don’t be discouraged, because almost every washing machine has a number of suitable programs in its arsenal, which will also suit us.

For washing a down jacket, the most delicate program is suitable, for example: washing wool, silk or other delicate fabrics. Please note that washing takes place at a temperature not exceeding 30 ° C. If such a temperature is provided by the program, then everything is fine, but if not, then you will need to reduce the washing temperature to the required one, using a special function (if any).

In addition to the washing program, you will need turn on the extra rinse function, if possible, or after the end of the washing process, start another rinse to better wash out the detergent from the down jacket, because, as you know, the down absorbs detergents very well and gives them very poorly.

It is also best to refuse the spin function, because at high speeds the fluff can go astray and even crawl out of the seams, which leads to damage to the thing.

After that, you can safely put the jacket in the washing machine and start washing.Then we just have to properly dry the down jacket.

How to dry a down jacket after washing

Now the washing of the down jacket has come to an end and we just have to dry it thoroughly, which we will now proceed to. To do this, first you need to remove the jacket from the washing machine and unbutton all buttons, zippers and other fasteners. It is also advisable to turn the pockets inside out so that they also dry well. Himself the down jacket does not need to be turned out until the very end of drying.

After washing, the fluff in a down jacket usually bunches up in its cells, so try to stir it up a little with your hands and distribute it evenly over the entire surface. Now you need to take the usual hangers and hang a jacket on them. In such upright and you need to dry the down jacket after washing in a washing machine, because it is in this position that water drains best and, accordingly, the down jacket will dry much faster than in a horizontal position.

During drying, regularly spread the fluff inside the jacket evenly so that it is properly located in the cells and dries faster.

Some fans of "quick results" very often dry a down jacket on batteries, with a hair dryer or other heating devices, not realizing that this procedure destroys the fluff inside the jacket.

Drying a down jacket in a washing machine

Again, to speed up the process, the hostesses use such a modern method as a tumble dryer or dry the down jacket in a washing machine with a drying function. We strongly discourage the use of this method as the process is completely destroys all thermal insulation properties of the pen and after such procedures, the down jacket will not be suitable for wearing in cold weather.

What to do if after washing the fluff in the down jacket is lost

If such a failure happened to you, then of course, for a start, it is best to identify the reasons why this happened. And this could happen if the rules for washing a down jacket were violated, or you chose the wrong washing program in the washing machine. But don't worry, there is a way out. If the fluff is very stray after washing, then the first thing to do is to try manually distribute it over the entire surface of the jacket. If this does not work, then you will need balls for washing down jackets, with which you will wash the down jacket again, following all the above tips.

If you follow all these recommendations, then you will not have to worry about the integrity of your down jacket after washing, because all our tips have been tested in practice and are confirmed by experts.